Hand Operated Chain Blocks

Hand operated chain blocks are self sustaining lifting equipment providing an easy means of lifting or lowering of a load with acceptable operative effort. They are designed for vertical lifting where the load is directly below the hook, but may be used with girder trolleys to move suspended loads along runway beams.

They are relatively light in weight and easy to install, so they suit temporary applications. Being operated by a hand chain, they can be high above the operator or the operator may be on a different level to the load. They are popular for maintenance purposes and ideal where there is no power. The larger capacities may require more than one person to handle and erect.

Selection Of Equipment

When selecting chain block, the user should be aware of the environmental conditions which exist and the effects such conditions can have on the components which make up the chain blocks.

All chain blocks have a brake mechanism which relies on sufficient torque, arising from the load lifted, to operate satisfactorily. There is therefore a MINIMUM load they can safely sustain as well as a MAXIMUM. The minimum specified is 5% of the equipment SWL. However exposure to a marine environment can increase the minimum load required to operate the machine. We therefore recommend that THE MINIMUM LOAD LIFTED SHOULD NEVER BE LESS THAN 10% OF THE SWL. When using a chain block you should also take into account the angle at is being used at, as this also reduces the SWL.

30 degrees 7/8ths of the SWL

45 degrees 5/8ths of the SWL

60 degrees ½ the SWL

Method of Attachment

The block may be of „suspended „or „built in „pattern, many manufacturers producing both options. Suspended types normally have a top hook by which the block is hung from and which allows a degree of articulation between the block and the supporting structure.

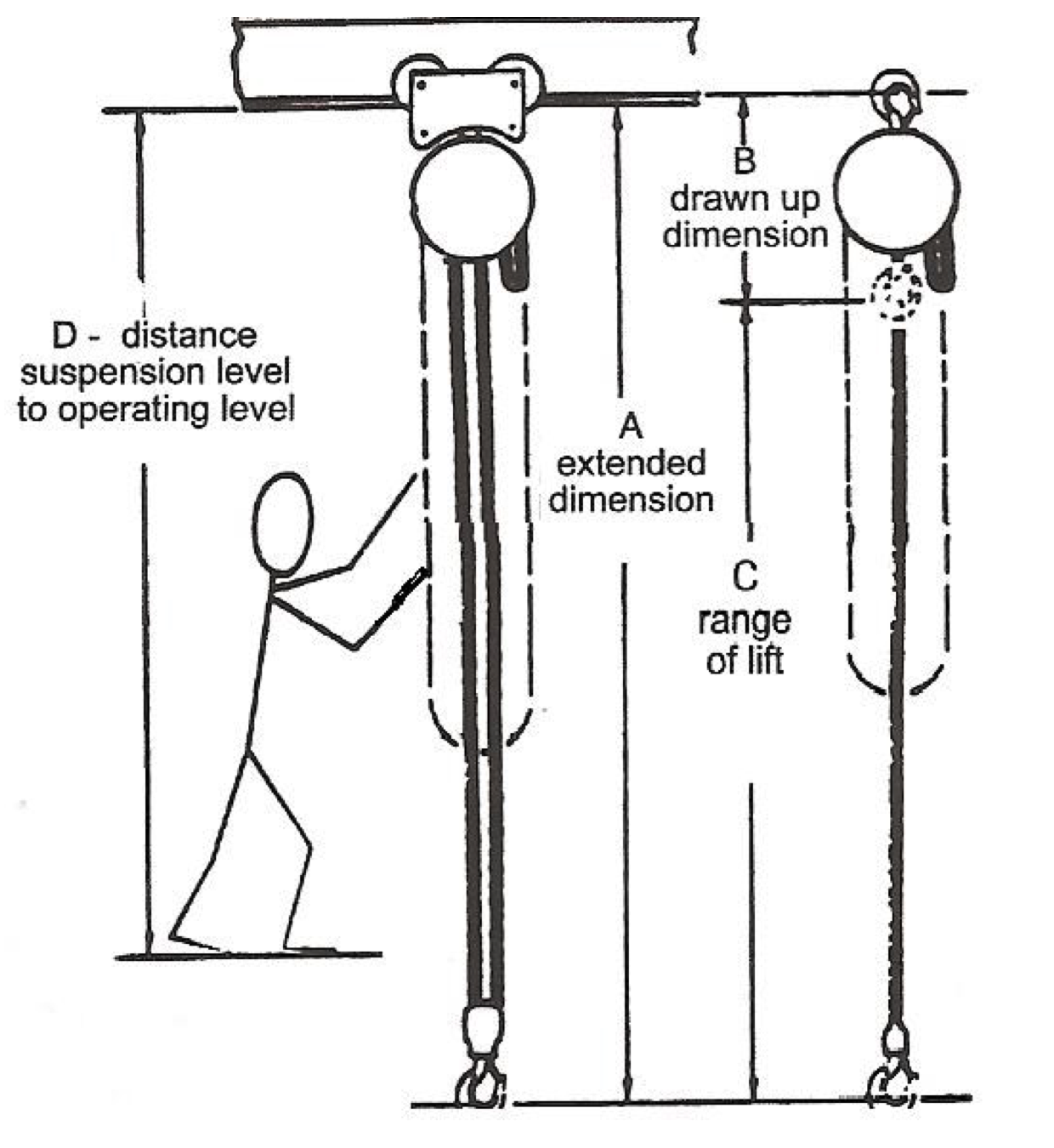

Number of Falls of chain

The lower capacity blocks e.g. 500kg, 1t lift the load on a single fall of load chain. Higher capacity blocks may be either be of similar design but with a larger frame or may utilize two or more falls of load chain. The various configurations available each have their own advantages and disadvantages with regard to weight, size, minimum drawn up dimensions, hand chain effort required and cost.

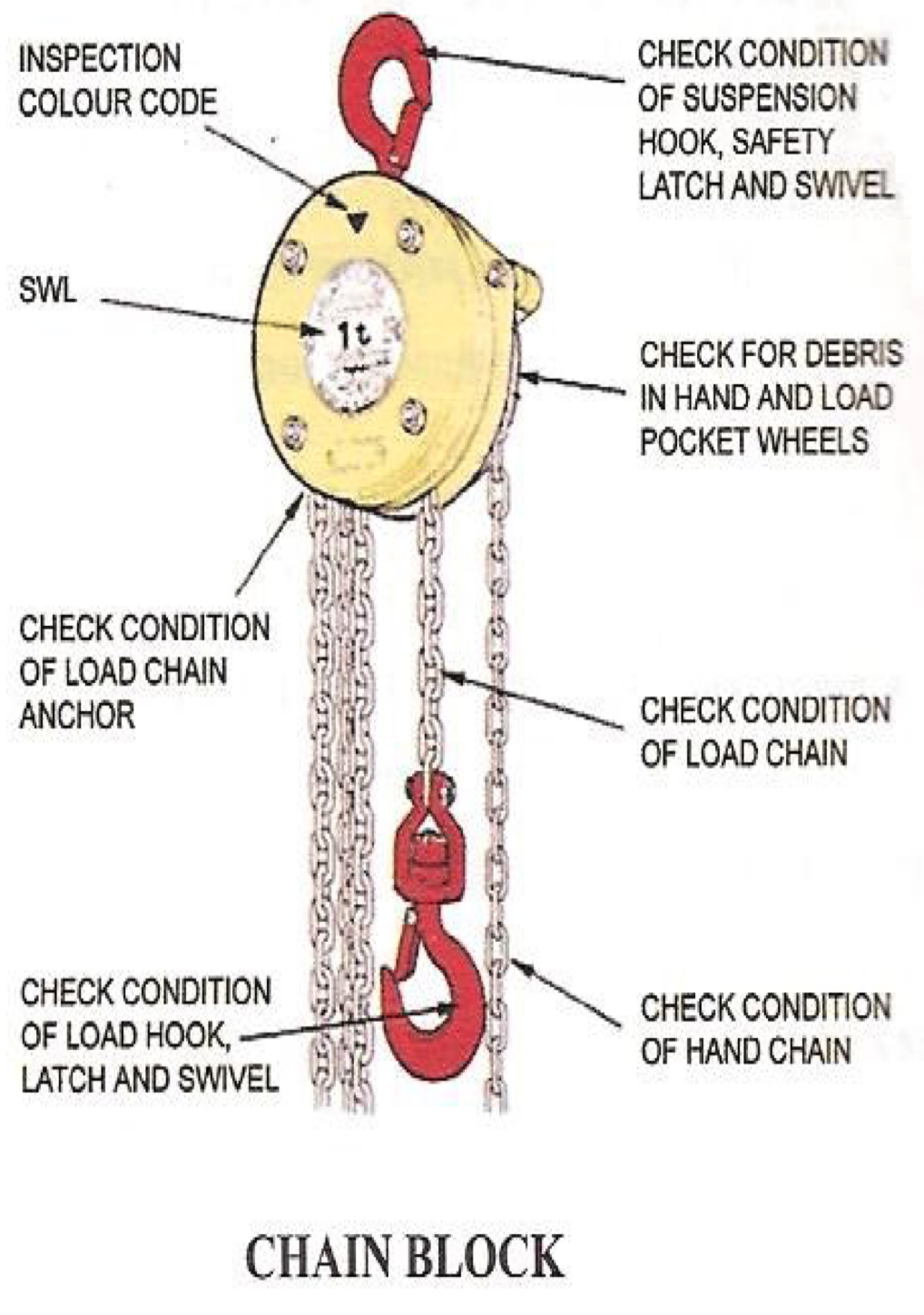

Chain Block Inspection

When inspecting the chain block the following needs to be checked :

- SWL

- Id Number

- CE Mark

- Colour code (if applicable)

- 2 x hooks

- 2 x swivels

- 2 x safety catch

- Load Chain

- Load chain fixing point to machine

- Load chain fixing to bottom hook

- Hand operating chain

- Guide wheels and pockets

- Body of the block

All of the above should be checked on a regular basis.

And all Lifting equipment should be checked every time before use and after use to ensure the user has not damaged the equipment.

It is also advisable that all Lifting Equipment is checked on a weekly basis whether it is in the rigging loft or in location to ensure the operational functionality of the equipment.

If it takes more than one person to operate the chain block there is a serious fault somewhere, and we should stop the operation and investigate what is wrong. The fault could be a variety of things as the load still secured to the deck or mounting points or the load is too heavy for the SWL of the chain block. NEVER OVERLOAD THE EQUIPMENT.